We use cookies to enhance your experience. By continuing to browse this site you agree to our use of cookies. More info.

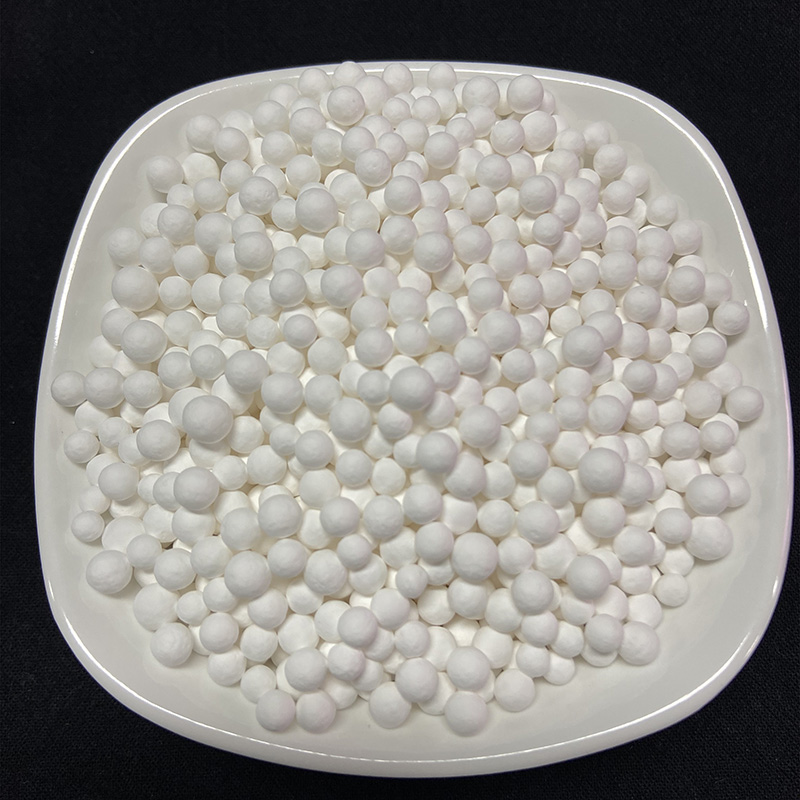

In terms of physical dimension and pure aluminum oxide content, aluminum oxide ceramic is the most widely accessible technical ceramic. When a designer is contemplating ceramics as a substitute for current metal applications or if the environment inhibits metals owing to excessive temperature, electrical, chemical, or critical wear, aluminum oxide, often known as Alumina, should be the first ceramic to examine. Molecular Sieve

The cost of the material in its as-fired state is not excessive, but if precise tolerances are required, diamond grinding and polishing are needed, which can significantly increase the cost and make the individual component more expensive than a metal part.

The savings could result from a longer life cycle or less downtime while the system is being repaired or replaced. Naturally, due to the application environment or constraints, specific designs simply cannot operate at all if they rely on metals.

Image Credit: INSACO Inc.-Machining of Hard Materials

The designer must also take into account the fact that all ceramics tend to be more fragile than most metals. Zirconium oxide ceramic, generally known as Zirconia, is an excellent alternative to consider if Alumina turns out to be brittle or prone to chipping in use. Zirconia is also very durable and resistant to wear.

Zirconia has a high resistance to impact due to its distinct tetragonal crystal structure, which is present in most 3% blends with Yttria. Zirconia enables fabricators to create delicate features and sharp edges that withstand rigorous treatment when combined with its fine grain size. Zirconia comes in two common grades: YTZP (Yttria blend) and MgO-PSZ (Magnesium blend).

Both raw materials have received approval for various industrial and medical and in-body uses. INSACO has connections with the producers of both materials and can suggest prospective raw materials suppliers for the designer to specify.

The designers of ceramic components for medical, aerospace, semiconductor, instrumentation, and industrial applications value INSACO proficiency in precise fabrication with complete QC documentation and material traceability.

Video Credit: INSACO Inc.-Machining of Hard Materials

This information has been sourced, reviewed and adapted from materials provided by INSACO Inc. - Machining of Hard Materials.

For more information on this source, please visit INSACO Inc. - Machining of Hard Materials.

Please use one of the following formats to cite this article in your essay, paper or report:

INSACO Inc. - Machining of Hard Materials. (2023, March 01). Technical Ceramics: Zirconia Alumina vs. Alumina Oxide. AZoM. Retrieved on March 01, 2023 from https://www.azom.com/article.aspx?ArticleID=22371.

INSACO Inc. - Machining of Hard Materials. "Technical Ceramics: Zirconia Alumina vs. Alumina Oxide". AZoM. 01 March 2023. <https://www.azom.com/article.aspx?ArticleID=22371>.

INSACO Inc. - Machining of Hard Materials. "Technical Ceramics: Zirconia Alumina vs. Alumina Oxide". AZoM. https://www.azom.com/article.aspx?ArticleID=22371. (accessed March 01, 2023).

INSACO Inc. - Machining of Hard Materials. 2023. Technical Ceramics: Zirconia Alumina vs. Alumina Oxide. AZoM, viewed 01 March 2023, https://www.azom.com/article.aspx?ArticleID=22371.

Do you have a question you'd like to ask regarding this article?

AZoM talks with Francis Wang, CEO of NanoGraf, to discuss their new lithium-ion battery technology and the onshoring of production in the Midwest.

AZoM spoke with Dr. Katharina Marquardt ahead of the 2023 International Day of Women and Girls in Science. We discuss her impressive career in STEM, spanning her expertise in subjects from mineralogy to ceramic materials.

This International Day of Women and Girls in Science, AZoM talks with Dr. Debrupa Lahiri, an associate professor in the Department of Metallurgical and Materials Engineering at IIT Roorkee, about her research and career in STEM.

This product profile from Microtrac outlines the high-end adsorption capabilities of the Belsorp Max X.

The APEX 400 is a dedicated solution for manual preparation of pressed pellets for XRF analysis. It is capable of pressing samples in supporting steel rings as well as in the standard unsupported format.

Find out more about how to run the lab more efficiently with access to all laboratory information using commercial web browser LabVantage 8.8.

AZoM.com - An AZoNetwork Site

Titanium-Aluminum Composite Carrier Owned and operated by AZoNetwork, © 2000-2023